THE BLOG

From rivets to riveting news, and far more about copper history than you could hope for, it's all here!

Read the Latest:

One of the most fraught debates in the copper world: what's the best lining for copper cookware? The answer: it's up to you!

my nightly

skincare regime

You can either type this featured post content manually or use a post look-up function in SHOWIT directly. It can also rotate between several posts.

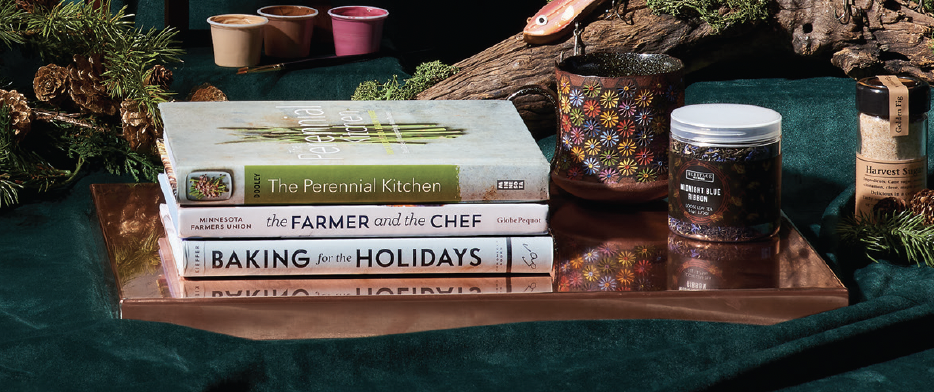

Popular Posts

browse popular categories

browse

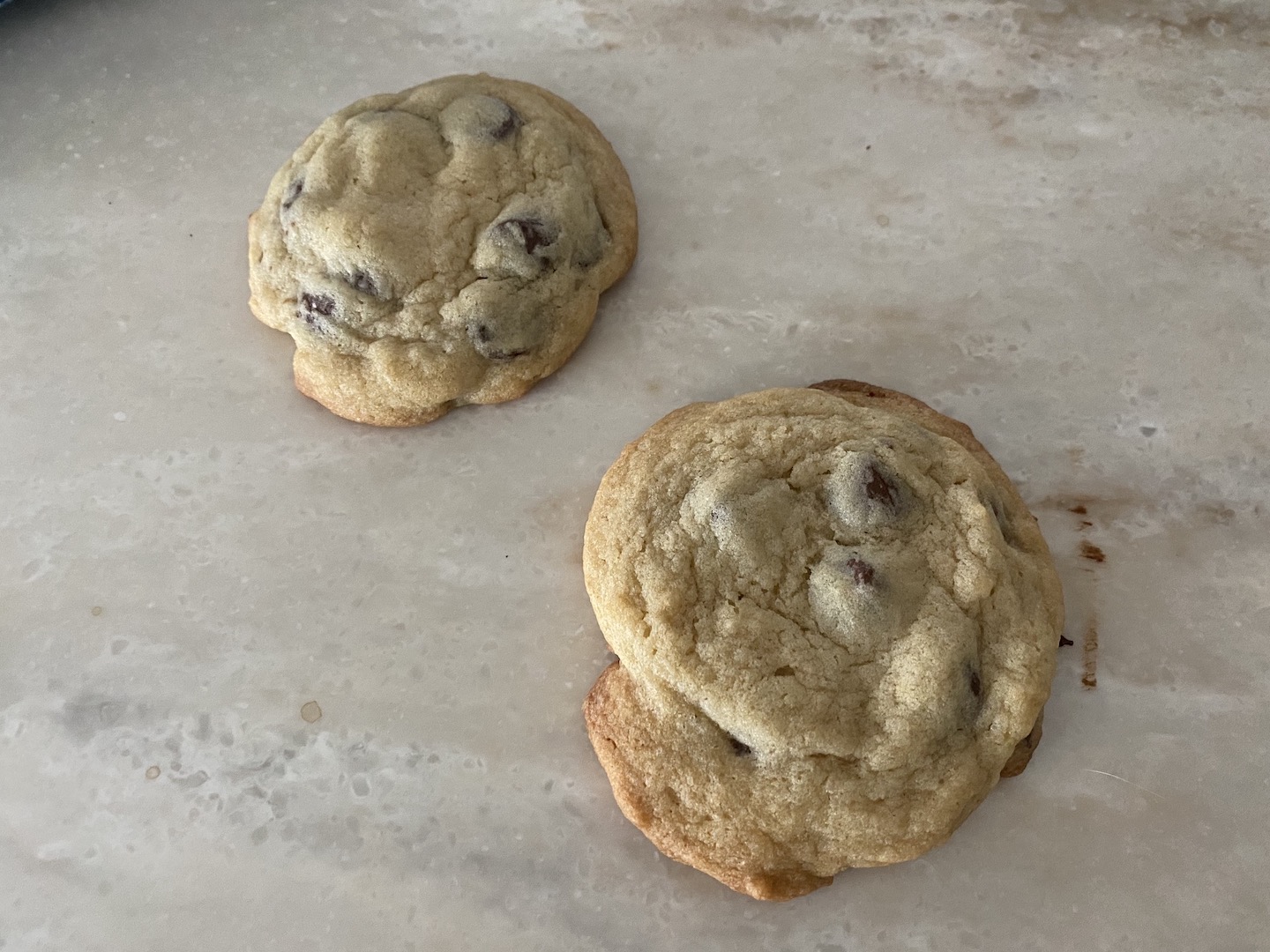

Recipes

Whether it's cooking in copper or cast iron, or maybe some baking, all the recipes here are tried and true and used often in this house. Even mac and cheese in a box!

browse

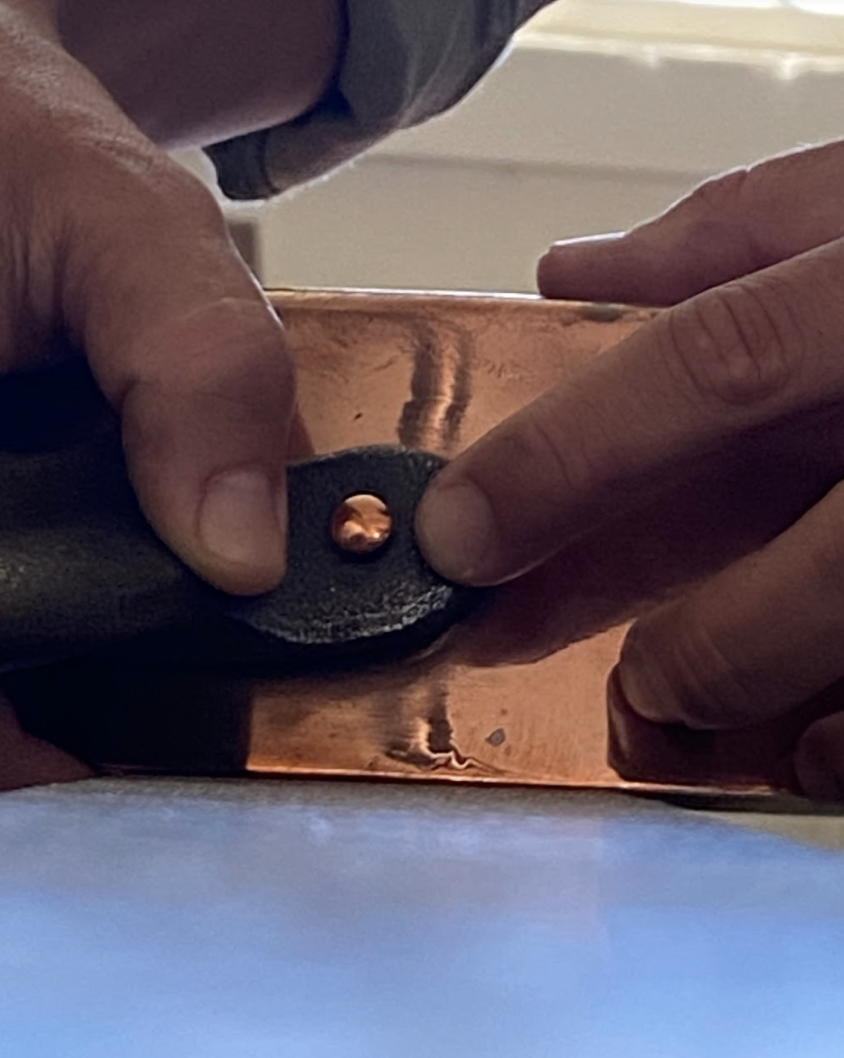

Smithing

Somewhere on here is how we made a jambonniere from scratch, and a lot about rivets and tinning. You're welcome to the rabbit hole...

browse

History

It all started with some research into cooking techniques of old...but copper and cooking go back a long way! Letters from me, the smith, to you, the chef, about where we and our food tools come from...

hello hello.

I’m sara,

YOUR happy coppersmith

Your cookware is always touched by my hands, personally. My three young children help pack boxes. My husband drives your order to UPS...

This is a family business, supporting other small, American family businesses. I do the physical work of the House Copper cookware line in my Wisconsin copper shop. My tools range from modern bead blasters and grinders to 1700s tinsmith stakes and 1820 hand rotary coppersmithing machines. Welcome to us!

coppersmith, novelist, farmer, herbalist, wife & mom

own the trade

Apply for future smithing classes

Get

hand

knowledge

If you're interested in a day class, a long weekend event, or a mini-apprenticeship, I offer several options at various times of the year.

want to chat?

drop a line. send a note. contact us!

You are welcome to submit thoughts, questions, and general inquiries here. (Though if you’re sending a note about re-tinning, custom orders, etc, it may get forwarded to my assistant.)

Please note! The address online for House Copper is NOT a storefront or forge. The copper shop is in my private home, and I do not allow drop-ins, surprise visits, or personal copper drop-offs. The address is a shipping address only. If you drive up, you’ll wind up at a UPS store, and they will not give you my personal home address.